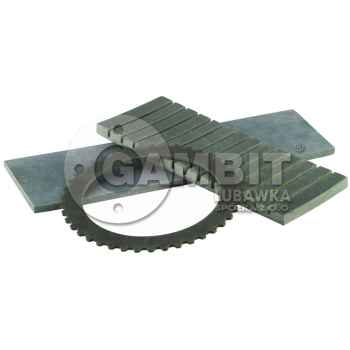

Sheeted friction linings

Structure of sheeted friction lining:

The friction lining produced by Gambit is an asbestos-free material, mould-pressed to customer's order, or pressed into sheets and cut to a customer's specification. Composition of materials applied and special regimented mixing and pressing processes allow production of homogeneous and reliable material of high friction coefficient in broad range of temperatures, low and even wear, as well as good performance, including low wear of mating surfaces, as well as quiet and stable operation. Significant use of components with high thermal conductivity ensures effective lining braking, also in applications when a braking cycle is highly intensive. Use of aramide fibres in sheeted friction lining ensures maintaining suitable elasticity and cracking resistance.

Application:

Sheeted friction lining is designated for application in disc brakes, drum brakes, conical brakes and other types of brakes applied wherever large braking forces are required; at high temperature during operation; and when high reliability of friction material and low wear of mating drum raceways is necessary. It is also recommended for use in equipment with high braking frequency. Upon customer's request we can produce reinforced and cut sheeted friction lining, designated for application in drum brakes.

Hardness categories and executions

Sheeted friction linings GC-E, GC-ES, GC-MK and GC-PZ 250 are produced in two standard degrees of hardness and manufactured according to a version chosen by a customer. The versions are marked as follows:

+ Z - reinforced with a metal net

+N - standard cut or in accordance with customer’s drawing

+6 - hardness from 55° to 65° Sh D / standard /

+8 - hardness above 75 ° D /very hard /

Examples of symbols:

GC – E + ZN6 - a lining reinforced with a net, chased, hardness

55° to 65° Sh D / standard /

GC - ES +8 - a lining with hardness above 75° Sh D /very hard /

GC – MK +Z – a net reinforced lining with standard hardness

By placing an order please specify a shape, dimensions and tolerances according to technical requirements for the needed type of lining and in correspondence to a customer's technical documentation.

|

Types of manufactured friction linings: Permissible working parameters: |

GC-E | GC-ES | GC-MK | GC-PZ |

| maximum unit pressure for a lining adhesion to a brake raceway [N/mm2] | 3,0 | 3,0 | 4,0 | 4,0 |

| maximum continuous temperature [oC] | 200 | 250 | 250 | 250 |

| maximum peak temperature [oC] | 300 | 300 | 350 | 300 |

|

minimum kinetic friction coefficient (measured with a CEZAMET apparatus) |

0,45 | 0,40 | 0,45 | 0,45 |

|

material wear: for +6 hardness [cm3/107J] for +8 hardness [cm3/107J] |

<2 <1 |

<2 <1 |

<1 <0,5 |

<2 <1 |

| density not higher than [g/cm3] | 2 | 2,1 | 2,1 | 2,5 |

| Caution: in order to evaluate the temperature correctly not only the ambient temperature in which the brake lining is assembled, but also a growth of temperature due to friction heat emission in a working area should be considered. In case of intense braking the temperature can locally grow by as much as 200oC. | ||||

All information in this catalogue is based on years of experience in manufacture and use of the discussed products. Since sealing performance in the joint is subject to multiple factors such as mounting method, system parameters, and sealed medium, technical parameters specified herein are of informative nature only and cannot be used as grounds for any claims; any special uses of products are subject to consulting with the manufacturer.