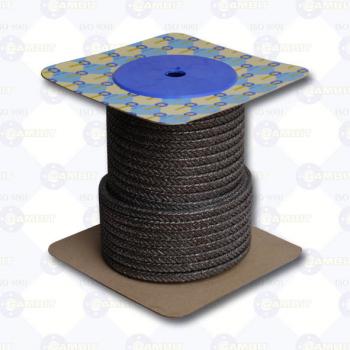

GRAPHITE PACKINGS

Expanded graphite is one of the best materials for manufacturing dynamic sealings. Its heat resistance ranges from - 200 °C to + 2000 °C. Unfortunately its heat resistance decreases in the effect of air, steam and other oxidants. It is therefore assumed that good brands of expanded graphite can be used in the air up to 450 °C, in dynamic applications up to 550 °C, and in static applications, e.g. in valves, up to 600 °C. Expanded graphite features very good chemical resistance to practically all media, with the exception of strong oxidants; good thermal conductivity and low friction coefficient for steel.

All information in this catalogue is based on years of experience in manufacture and use of the discussed products. Since sealing performance in the joint is subject to multiple factors such as mounting method, system parameters, and sealed medium, technical parameters specified herein are of informative nature only and cannot be used as grounds for any claims; any special uses of products are subject to consulting with the manufacturer.