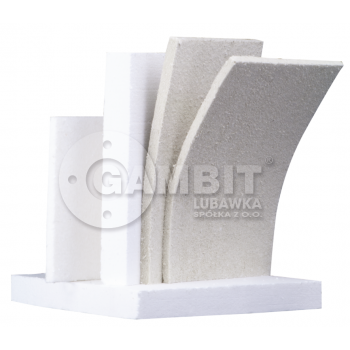

Vacuum formed products - CV 1150 BIO type

GENERAL INFORMATION:

CV type vacuum formed thermal insulation products are made of mineral alkaline earth silicate fibres (AES) with a classification temperature of 1300⁰C (EN 1094-1) and a binder. They are characterized by high thermal resistance, low thermal conductivity, low density and excellent resistance to temperature changes. Due to the excellent thermal insulation, resistance to thermal shock, thermal resistance and ease of machining (also mechanical - milling), these products are used in power industry, metallurgy, foundry and the ceramic industry. CV thermal insulations are used as linings of furnace cars, fi llings of expansion joints, protections of riser heads in foundries, protectionsof thermocouples, high temperature gaskets, foundry spouts, and others in working temperatures up to 1150⁰C

The advantages of using CV type vacuum formed thermal insulation products:

• reduction in furnace weight

• extension of lining lifecycle, especially in batch furnaces

• reduction in costs and time of repairs and overhauls

As a standard, CV boards are produced in a hard and flexible version in the formats 1000x1000 mm and 1000x500 mm, thickness from 8.0 mm to 200 mm, over 200 mm the boards are glued. We also produce CV shapes: pipes, cylinders, cones, plugs, arches, rings and gutters.

| TYPE CV | DENSITY | THERMAL CONDUCTIVITY | |

| [kg/m3] | t [oC] | λ [W/mK] | |

|

CV-1150 BIO (hard) |

250 | 20 | 0,066 |

| 200 | 0,072 | ||

| 400 | 0,113 | ||

| 600 | 0,167 | ||

| 700 | 0,204 | ||

| 800 | 0,245 | ||

| 700 | 0,204 | ||

| 800 | 0,245 | ||

| 900 | 0,292 | ||

| 1000 | 0,349 | ||

|

CV-1150 BIO (elastic) |

160-200 | 20 | 0,05 |

| 200 | 0,08 | ||

| 300 | 0,09 | ||

| 500 | 0,14 | ||

| 700 | 0,22 | ||

| 900 | 0,39 | ||

.

All information in this catalogue is based on years of experience in manufacture and use of the discussed products. Since sealing performance in the joint is subject to multiple factors such as mounting method, system parameters, and sealed medium, technical parameters specified herein are of informative nature only and cannot be used as grounds for any claims; any special uses of products are subject to consulting with the manufacturer.