FABRIC EXPANSION JOINTS

General information

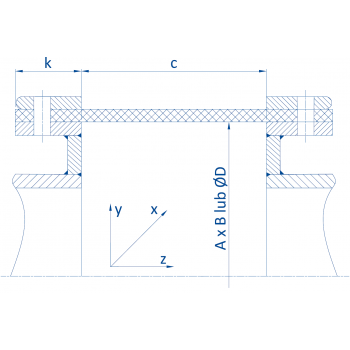

Industrial processes require a possibility of a flexible joint of two or mere components that move against each other, in such a way as to maintain tightness of the connection. The solution of this problem are compensator fabrics produced by Gambit in accordance with individual needs of users or installation designers. They are used as flexible joints compensating thermal deformations, side shift, and vibrations, while muffling and reducing transfer of noise across the installation. Compensators are used in power plants, gas turbines, chemical industry, petrochemical industry, paper industry and cement industry. More and more compensators are used in exhaust gas treatment and desulphurisation. Our compensators are made of materials resistant to both high temperatures, up to 1000oC, and aggressive chemical media. Working pressure of compensator fabric is -0.2 to 0.3 bar.

Application of compensator fabrics has a number of advantages. Thanks to high elasticity with minimum installation space required, small forces required during assembling and installation, and easy retrofitting, they can transfer and compensate displacements in all directions at the same time. Thanks to adoption of impenetrable materials (such as PTFE) they ensure high tightness of joint at a wide range of temperatures and media.

All information in this catalogue is based on years of experience in manufacture and use of the discussed products. Since sealing performance in the joint is subject to multiple factors such as mounting method, system parameters, and sealed medium, technical parameters specified herein are of informative nature only and cannot be used as grounds for any claims; any special uses of products are subject to consulting with the manufacturer.