COMPRESSION (BRAIDED) PACKING

Braided packings are the most common sealings used in stuffing boxes of pumps and fittings. Easy-to-apply, versatile, long-lasting and relatively cheap, they are continuously a subject of users’ interest, although the number of alternative solutions is growing steadily. Implementation of advancements in material engineering, new materials and ever further specialised material and design compositions, allow obtaining better and more durable sealing solutions, provided correct mounting and operation is ensured.

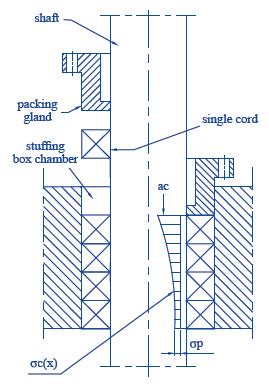

Operating principle of braided packing. Properly cut sections of braided packing placed in the stuffing box form a package (Fig.1).

The design of such a package, or each segment thereof, allows its pressing to a lateral surface of the stuffing box and to a shaft or a spindle. The pressing

should be strong enough to cause compression of the sealing material and filling of all irregularities in surfaces of mated shaft and stuffing box. Since one of the mated surfaces is moving, good packing should flexibly follow the run-out or lack of alignment

of a shaft or a spindle.

Majority of irregularities in operation of stuffing box sealing is a result of incorrect matching of packing to working conditions or incorrect mounting, so keeping predetermined mounting procedure is essential.

All information in this catalogue is based on years of experience in manufacture and use of the discussed products. Since sealing performance in the joint is subject to multiple factors such as mounting method, system parameters, and sealed medium, technical parameters specified herein are of informative nature only and cannot be used as grounds for any claims; any special uses of products are subject to consulting with the manufacturer.