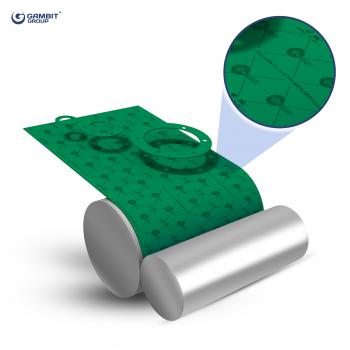

COMPRESSED FIBRE SHEET (INCLUDING REINFORCED SHEETS)

GAMBIT AF series asbestos-free gasket sheets are state-of-the-art materials for technical sealing of various media, and for application in a broad range of temperatures and pressures. These products are composites of top quality aramide fibres, specially composed inorganic fibres, and fillers, as well as elastomers selected for specific working conditions. Highly specialised calendering process of sheets, meeting the requirements of ISO-9001, guarantees high and stable quality.

Technical parameters of GAMBIT AF sheets meet the requirements for the majority of applications. Wherever specific working conditions prevent using GAMBIT AF sheets we offer sheets based on expanded graphite, expanded vermiculite, or PTFE. All these products offer the highest level of quality and reliability.

NOTES ON SELECTION AND MOUNTING OF GASKETS MADE OF GAMBIT GASKET SHEETS

When selecting the material for sealing of individual nodes, consider the following factors. The most important are working temperature and pressure, type of sealed medium and joint design. There are also other factors affecting the effectiveness of sealing, such as cyclical nature of operations, mechanical vibrations, precision of mounting or technical condition of flanges.

Data and T-P diagrams referred to in this catalogue allow to select the material that best suits the requirements with regard to working conditions of a given joint. Consider also that the working parameters should be within the suitable area of the diagram. This does not mean that the sealing cannot, in some cases, be effective when working parameters fall outside of the diagram. However, such a situation requires consulting our technical support team, or running trials.

In order for the sealing to work long and stable, it is necessary that certain requirements are met concerning flanges, bolts and mounting. The key is to ensure parallel and flat arrangement of mating flanges. Only then the whole sealing surface is under mounting load exceeding that required by calculation procedures and, simultaneously, the stress does not exceed the value damaging the gasket under working conditions. In practice, however, there is a number of cases where torque spanners cannot be used during mounting. In such case we recommend to exert such pressure between flanges that the gasket is compressed by 8-10% of its original thickness. Such pressure is sufficient, in most cases, to tighten the joint without causing damage to the gasket. To the same end we recommend using identical bolts for the whole joint. They should be in good technical condition and coated with high-quality lubricant.

Gasket sheet material is a composite made of organic and inorganic components. It can work efficiently at temperatures preventing the use of some of its individual components. You should however be always aware of specificity of the material, its strengths and weaknesses.

All gaskets of aramide and rubber sheets harden at temperatures above 200°C. Good sheets, such as GAMBIT sheets, even then remain elastic enough to compensate for thermal movements of flanges within the temperature range as specified in this catalogue. This is the basic requirement for keeping the sealing tight, especially in the case of nodes subject to thermal cycles.

Another threat to aramide and rubber sheets at temperatures above 380°C is oxidation. This process causes elastomer binding the sheet to burn out. In order to prevent it, the elastomer component is to be isolated from chemical effects of both sealed medium and ambient oxygen. This goal can be achieved in two ways. First is suitable flange design, e.g. tongue/groove. Second is jacketing (securing gasket edge with metal). Jacketing is to be so executed that it protects the composite material from ingress of the medium, but permits response to thermal movements and vibrations of a flange joint. Jacketing acts as mechanical reinforcement of the gasket, protects against diffusion of sealed medium via the gasket material, and, most of all, protects the composite materials of the gasket against adverse chemical effects of the sealed medium and the environment.

Correctly assembled flange joint, with properly selected and mounted gasket, allows to maintain tightness for a long time. It is prohibited to reuse gaskets once removed.

All information in this catalogue is based on years of experience in manufacture and use of the discussed products. Since sealing performance in the joint is subject to multiple factors such as mounting method, system parameters, and sealed medium, technical parameters specified herein are of informative nature only and cannot be used as grounds for any claims; any special uses of products are subject to consulting with the manufacturer.