GAMBITGRAF gasket cut from a graphite sheet

Flat gaskets cut from GAMBITGRAF LUX graphite sheets with 99.5% purity of expanded graphite, reinforced with a tanged steel core. Highly pure graphite, sulphur content less than 300 ppm and content of chlorides less than 50 ppm considerably reduces corrosion processes in the sealed joint and increases resistance to high temperatures.

We produce gaskets in accordance with the received technical documentation. In case the tolerance of the gaskets is not specified, we use the 14th accuracy class as the standard.

Gaskets with dimensions larger than a gasket sheet format are made in form of the so-called puzzles for self-assembly.

Working conitions (parameters):

Temperature: -200÷500°C (max. 550°C in steam)

Pressure: to 12 MPa

|

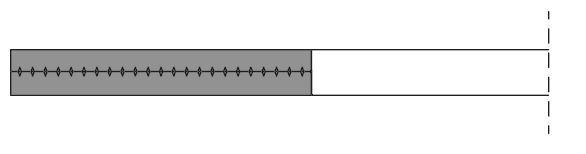

GAMBITGRAF Flat gaskets cut from expanded graphite sheets reinforced with a tanged acid-resistant steel insertion. The most frequently used gasket type for universal application in various flanges, has an ability to reach high tightness with a relatively low assembly stress. High purity of expanded graphite limits corrosion processes in a sealed joint. |

|

|

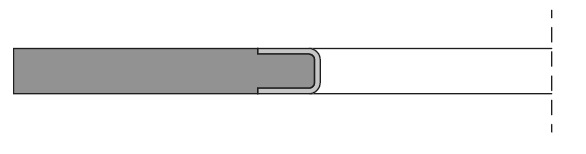

GAMBITGRAF I Inner eyelet gasket with an acid-resistant steel. Such a solution secures the sealing material from an influence of sealed medium and reinforces the gasket mechanically. |

|

|

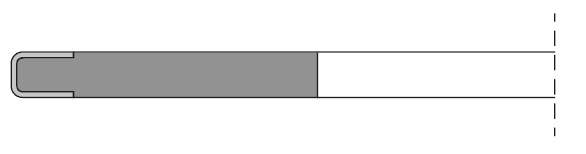

GAMBITGRAF O Outer eyelet gasket with an acid-resistant steel. Such a solution secures the sealing material from an influence of surrounding medium (usually air) and reinforces the gasket mechanically. |

|

|

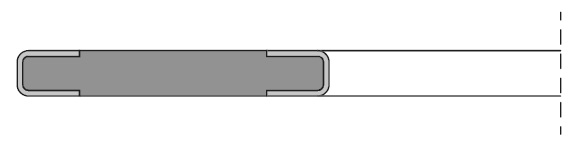

GAMBITGRAF IO Inner and outer eyelet gasket made of metal secures the gasket material from negative influence of sealed medium, surrounding medium and cladding mechanically reinforces the gasket. |

remarks:

All metallic eyelet gaskets are made for the thickness of 2 mm only. We produce outer metallic eyelet gaskets from the diameter of 200 mm.

All information in this catalogue is based on years of experience in manufacture and use of the discussed products. Since sealing performance in the joint is subject to multiple factors such as mounting method, system parameters, and sealed medium, technical parameters specified herein are of informative nature only and cannot be used as grounds for any claims; any special uses of products are subject to consulting with the manufacturer.